Step 1:

Center of Axle Normally Center Bolt Hole in Bottom Lip

Measure Opening in Tub

Center tub on Mark

Step 2:

Place Tub on Bed Side

Even Lip on Tub with Bottom Bed Lip

Take Fine Point Sharpie – Mark inside of Tub

Step 3:

Using Magnetic Pin Stripper Tape

Place on Bed Side where Plasma will cut 1/8″ Outside of Mark

Can also be done with jigsaw with fine tooth Blade

Step 4:

Plasma cut out for Tub

Remove Panel

Step 5:

Place Tub back in hole

Mark Bottom Lip

Bed Side – Saw out for Tub Lip

Step 6:

Take Grinder – Grind 1″

Needs to be Ground all way round where Lip will be Bonded

Step 7:

Deburr back side if using Plasma

Step 8:

Check Fit of Tub

Step 9:

Grind Lip on Tub

Step 10:

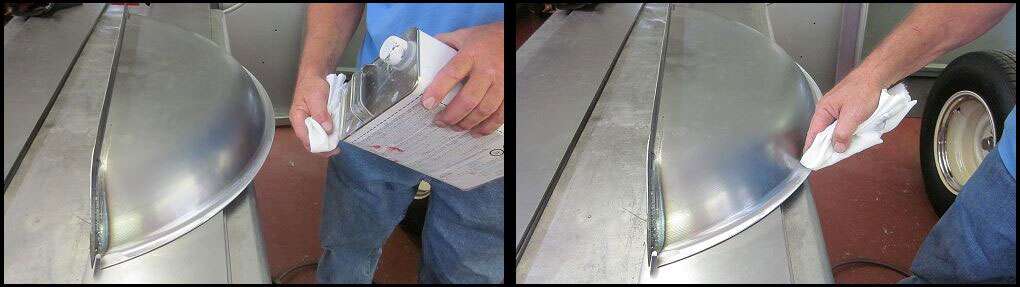

Put Lacquer Thinner on Rag, & Clean Tub & Bed Side

Blow off all Lint from Rag

Step 11:

Using 3M Epoxy Metal Bond with Solid Bead

Panel Bond Adhesive 3M #8115

Step 12:

Place Tub back in Bed Side

Line up Lip at Bottom

Step 13:

Begin with Clamps & Heavy steel to set.

Leave overnight to Bond.

Step 14:

Next day Weld Tub Lip to Bottom of Bed Lip

Step 15:

Place board under Bed Lip

Mark outside & inside of board

Step 16:

Board is marked & ready

Used Dremel to clean up edge

Step 17:

Jigsaw cut first mark on board

Step 18:

Grind 1/8″ for tub to fit

Step 19:

Stain to match original color.

Step 20:

Boards are finished and ready to install.

Step 21:

This is a fitted and installed wheel tub.

For any questions or concerns with your install, don’t hesitate to email us at info@ls-fab.com

Outstanding work on the instructions but what’s your recommendation on what to use to between the bed and the wheel tub on the inside? No cut will be perfect when cut by hand, there would some small imperfections that I believe can be hidden by a beat of silicone or other product.

TIA

Seam sealer is what they use in the newer automotive applications. It’s also paintable, unlike silicone. Should make a nice finish.